Our letterpress cards are both tactile and visually striking, each ink is embedded into the luxurious paper.

Key Features

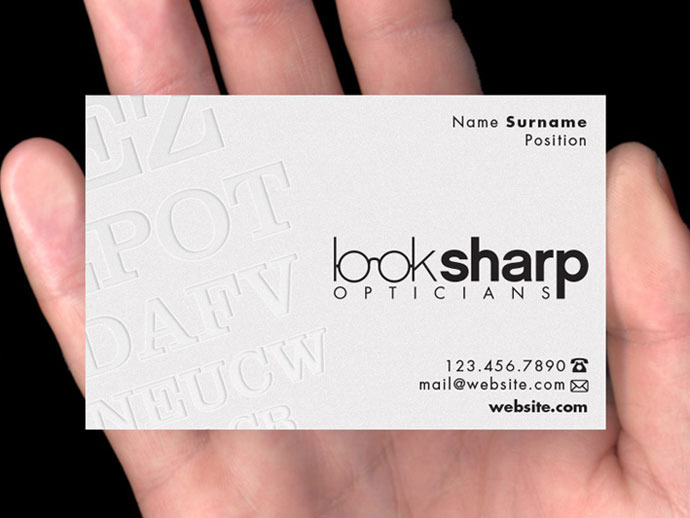

Debossed Print

Each card is painstakingly handcrafted using traditional artisanal techniques. We first etch the artwork into a metal block. We then use this to gently embed each ink into the surface of the luxurious paper stock. This gives a uniquely visual and tactile appearance to the business card quite unlike that found by using any other printing process.

Kind To The Planet

As well as being fully recyclable and biodegradable, the paper used has FSC certification and is sourced from managed forests. It’s free of heavy metals and is classified ECF. We only print with eco-friendly inks containing sustainable vegetable oil instead of mineral oil and we use biodegradable water-based adhesive to laminate the three layers of paper forming the card.

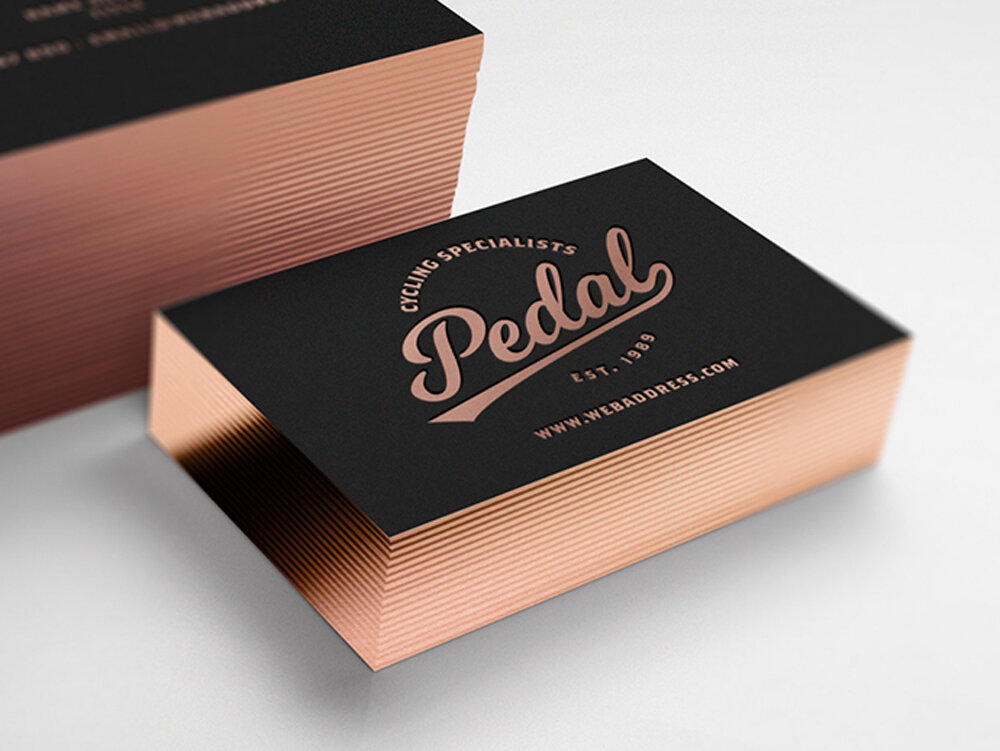

Metallic inks

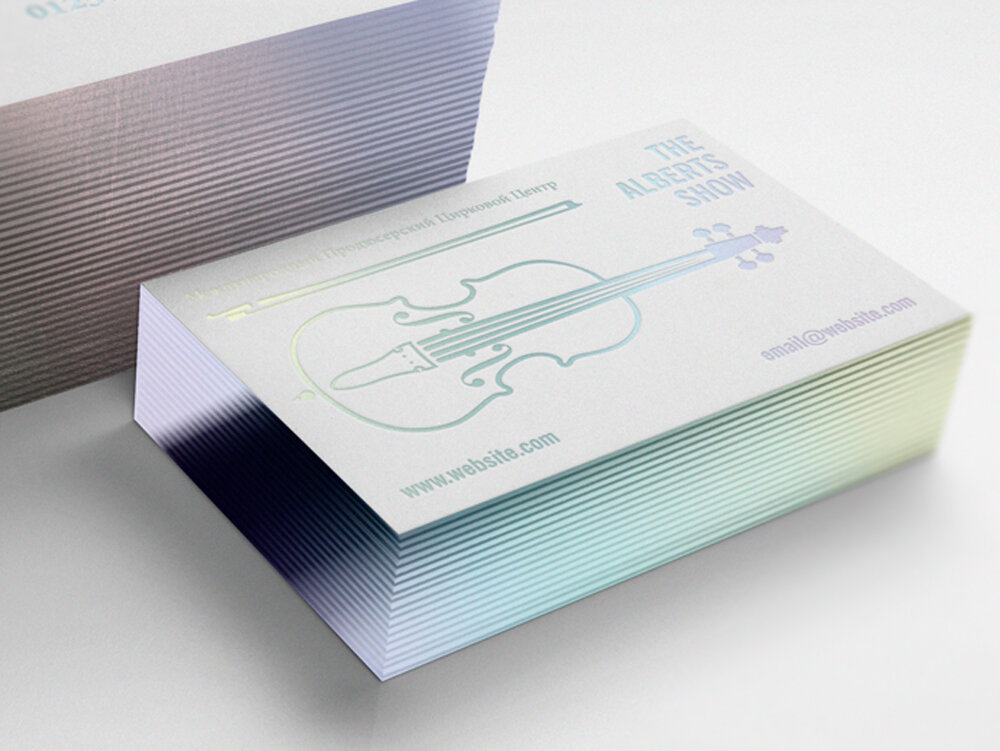

In addition to conventional pigment colours, we’re able to apply stunning metallic inks to the gently textured surface of the card. Our curated range of metallic colours are vibrant and eye catching. We even stock a diffraction ink that splits the white light hitting it reflects into the colours of the spectrum.

Custom paper Colour Combo’s

Does your branding demand a particular combination of paper colours? No problem. On orders of 500 cards or more we’re able to customise the shades used for each of the triplex card’s layers at no extra cost. A total of 40 different colours are available, giving 64,000 possible combinations. The colours available can be seen here.

Coloured Cores

Our letterpress cards comprise of three layers of genuine Colorplan paper. This seam of colour running through the centre layer of the triplex stock is visible when viewing the edge of the card, giving it a unique finishing touch.

Gilded Edges (OPTIONAL)

This highly specialised printing technique involves applying a reflective foil to the edge of your letterpress business cards adding that extra touch of elegance. We offer edge gilding in silver, traditional gold, rose gold and even holographic foil.

As well as being fully recyclable and biodegradable, the pulp used is sourced from managed forests.

In addition to optional gilded edges, we offer a selection of eleven colours for the core layer of the card. When combined with the outer two layers it forms a luxuriously thick triplex card, at 900g per sq/m.

We apply the inks one by one, gently embedding them into the surface of the stock using etched metal blocks, resulting in the subtle deboss effect so synonymous with the letterpress printing technique.

Free Design Service

Designing a letterpress card is no picnic. Fortunately, we provide a completely free design service to all customers who don’t already have artwork. Once we have collected a few pieces of information, our design team will put together an initial concept. We then create a photo-realistic digital mockup using our innovative proofing system. This shows how the card would look once produced. Using your feedback, we make revisions until you are 100% happy with the layout.