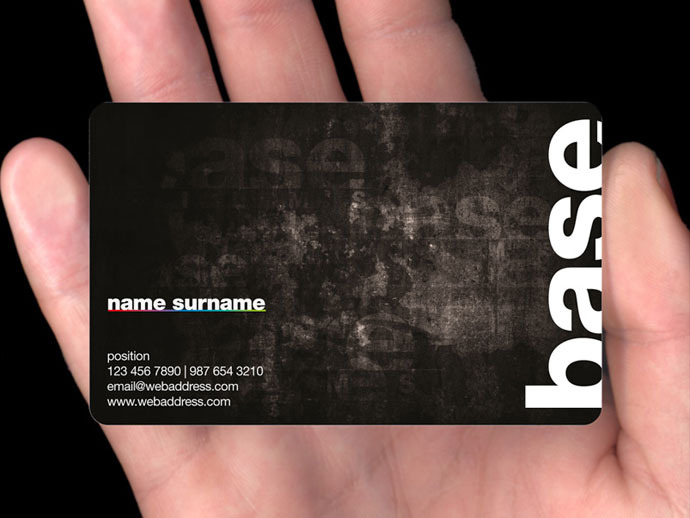

Our full colour plastic cards are durable. Really durable. Unlike many mass produced plastic cards, we encapsulate the digitally printed artwork between two thick sheets of crystal clear PVC.

Key Features

GLOSSY OR MATT SURFACE FINISH

Our customers can choose between glossy or matte finish on the surface of their cards. The printed artwork is sandwiched between two crystal clear sheets of sturdy PVC. Heat is applied to ensure a good bond between the artwork and protective coating. The gloss or matt finish is added to the outside surface of the PVC by using either polished of sandblasted metal plates respectively. These plates are used to apply the heat and pressure required to fuse the three layers into one. The result is a finish that is integral to the structure of the card rather than a fragile coating.

THREE THICKNESSES

By varying the density of the crystal clear PVC sheets, we can offer the full colour plastic cards in three thicknesses. Our thickest card, 760 microns, is the same as a standard credit card. Our thinnest, at 420 microns, is a more cost effective solution. Providing a good middle ground is our 680 micron card.

PHOTOS & GRADIENTS

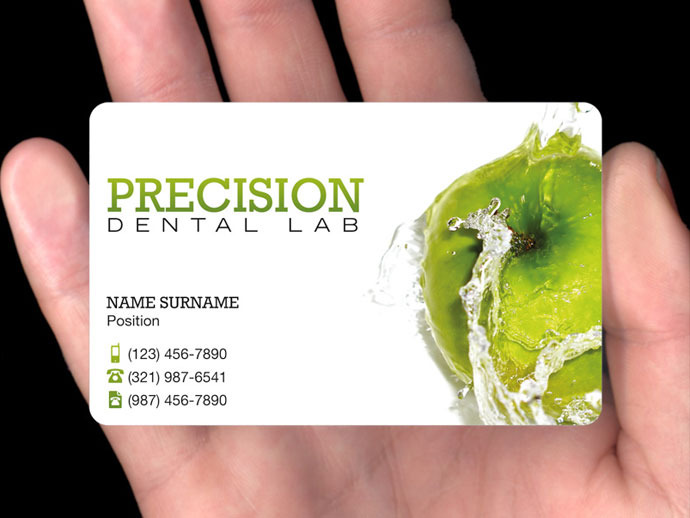

Our full colour plastic business cards are particularly suited to photographic images and graphics that include gradients. The digital printing presses use a conventional CMYK reproduction process, capable of a wide colour gamut.

Optional personalisation

Our full colour plastic cards can be optionally personalised in a number of ways, including sequential numbering, the addition of signature panels or QR codes. Coupled with their exceptional durability, they are the perfect solution for membership cards or loyalty schemes.

The business card artwork is digitally printed in full colour on to both sides of a strong but wafer thin sheet of opaque plastic.

Thick crystal clear PVC sheets are applied to both sides. Heat and pressure are applied to both sides using perfectly flat metal sheets. The clear plastic sandwich is fused to the printed artwork inside.

Free Design Service

We provide a completely free design service to all customers who don’t already have artwork. Once we have collected a few pieces of information, our design team puts together an initial concept and first draft. We then create a photo-realistic digital mockup using our innovative proofing system. This shows exactly how the card would look once produced. Using your feedback, we make revisions until you are 100% happy with the layout.